|

Home - New technologies - Preparation of alcohol

Removal of mechanical impurities from alcohol taken over from shipping containers and alcohol storages

Filter elements

|

Grade

|

Filter medium

|

Retention efficiency, μm

|

Properties

|

Brief description

|

|

EPNS

|

12Kh18N10T stainless steel mesh

|

5, 10, 20, 40, 70

|

pleated mesh

|

The mesh filter features a high production rate, a long service life, the possibility of full regeneration and multiple repeated use. Operating temperature in polypropylene housing: 90°C, in metal housing: 200°C. Used for coarse prefiltration of alcohol, alkali and water.

|

The grade of the DS filter holder accommodating various numbers of filter elements of various height is selected depending on the production rate of the system, 300 to 500 l/h for one 250 mm high element.

Removal of bitter stuff from alcohol by using EPSF.U sorptive filter elements

We introduce the new EPSF.U sorptive filter element for removal of bitter stuff from alcohol and water-alcohol mixtures in production of alcoholic beverages.

Description

The technology is based on EPSF.U cartridge filter elements loaded with natural activated carbon.

EPSF.U filter elements are produced using the technology developed by Technofilter Research-and-Manufacturing Enterprise Ltd on the basis of natural activated carbons that ensure the running of catalytic reactions. Enhanced catalytic agglomerated activated carbon in EPSF.U filter elements has several characteristics that account for its exceptional properties retained throughout the service life of the filter element.

The carbons concentrate reactants by adsorption, facilitating thereby their interaction of pore surfaces. Although carbon contained in filter elements is not impregnated with metals or alkali, it possesses catalytic properties of these materials.

On the basis of the 250 mm module, 500, 750 and 1000 mm high elements are made by thermal welding.

Main applications

- Processes of sorptive purification of alcohol-containing liquids.

- Adjustment of tastes and odours, removal of ammonia, amines and nitrates from beverages at enterprises of food industry.

Operating recommendations

Recommended rate of filtration for removal of bitter stuff from alcohol and water-alcohol mixtures is 20 to 40 l/hour for one 250 mm high element.

Depending on the required processing rate, the number and height of filter elements, the grade of the DS filter holder or the filtration system are selected.

Improvement of organoleptic properties of alcohol by using Silver Filtration technology – EPSF.UAg 0.4

Designation: additional treatment of alcohol for the purpose of improving its organoleptic properties.

Features and advantages of Silver Filtration technology

|

Features

|

Advantages for the consumer

|

|

Stable quality of alcohol

|

- Smooths out unpleasant tastes and odours of alcoholic tones in the flavour.

- Stabilizes organoleptic properties of alcohol before preparation of the water-alcohol mixture.

- High efficiency of alcohol treatment by using EPSF.UAg 0.4 filter elements incorporating silver-impregnated cocoa carbon

|

|

Prompt and easy maintenance

|

- Prompt and easy replacement of filter elements.

- High processing rate of alcohol: 25 to 30 dal/hour for one 250 mm high element

|

|

Large throughput of EPSF.UPt filter elements (minicolumns) with minimum expenses

|

- Average throughput of 250 mm high minicolumn is up to 10,000 dal

|

The technology is based on EPSF.UAg0.4 cartridge filter elements based on activated silver-impregnated coconut shell carbon. The technology is based on EPSF.UAg0.4 cartridge filter elements based on activated silver-impregnated coconut shell carbon.

The technology has been patented by Technofilter Research-and-Manufacturing Enterprise Ltd. (Patent No 2222586, Silver Filtration method for treatment of the water-alcohol mixture used in production of vodka and cartridge filter).

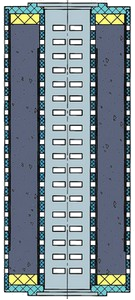

The EPSF.UAg0.4 filter element is a carbon “minicolumn”: carbon is loaded between outer and inner shells. This design takes into account the ability of carbons to swell in the course of operation and precludes the possibility of “channelling” even at high filtration rates.

On the basis of the 250 mm module, 500, 750 and 1000 mm high elements are made by thermal welding. Depending on the required water-alcohol mixture processing rate, the number and height of filter elements as well as the grade of the filter holder or USF filtration system are selected.

|