|

Home - Carbon processing

Carbon processing is a special process in production of vodka, that can regarded as the main one. Indeed, filtration through carbon results in a miracle: a virtually ready-for-use VODKA is produced from two mixed components – alcohol and water. It only remains to give several additional touches to it, and, voila, it is already in a bottle with a neat label.

According to William V. Pokhlyobkin, the modern vodka is not only a result of the tradition of using natural means in both main raw materials and purification methods developed on the basis of multi-century experience, but also a result of profound scientific research and calculation that guarantee the production of a chemically pure, harmless product.

Two main opinions on carbon processing are common:

1. It is believed that genuine vodka is the one filtered through birch coal.

2.It is believed that among all existing methods of carbon processing of the water-alcohol mixture, the most effective method is filtration through a carbon column (dynamic method). In view of its broad use, this method is considered classic.

Let us consider these opinions more closely.

Carbons

Nowadays there are not many people who are aware of the fact that the vodka we know is not the product that was produced several centuries ago. What do we mean? You will realize that when you read the section “The history of vodka”. Let us single out the main points.

It was in the 1930s that the vodka production technology was legally approved and the term “vodka” was officially introduced. In the following years of the 20th century the technology was somewhat additionally developed.

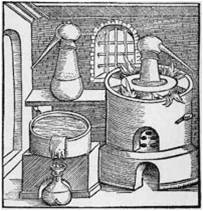

Vodka, initially called “bread wine”, “hot wine” (hence Ukrainian “gorilka” – “burnt wine”), was at that time a product made by several distillations using natural flavours. Much attention was paid to purification from impurities affecting the taste, odour and safety of the product. Purification was carried out with natural coagulators such as milk, whole eggs and eggwhite. Sometimes newly-baked brown bread was used as a coagulator, usually as an initial coagulator of milk. Vodka, initially called “bread wine”, “hot wine” (hence Ukrainian “gorilka” – “burnt wine”), was at that time a product made by several distillations using natural flavours. Much attention was paid to purification from impurities affecting the taste, odour and safety of the product. Purification was carried out with natural coagulators such as milk, whole eggs and eggwhite. Sometimes newly-baked brown bread was used as a coagulator, usually as an initial coagulator of milk.

In 1785 the great Russian chemist T.Ye.Lowitz established by prolonged experiments with wood charcoals and various products – food acids, honey, water, alcoholic solutions, etc. – that treatment of “bread wine” with carbon can significantly improve its taste properties without halving (T.Ye.Lowitz. A new easy method of removing objectionable odour and taste from bread wine without rectification – Saint-Petersburg, 1785). Due to partial oxidation of alcohol to acetic acid and acetic ether the resultant product had a soft taste and a special odour that was subsequently associated with vodka.

This investigation opened a new epoch in production of vodka. The technology became widespread and remains the main one until now.

Initially, coals such as beech, lime, oak, asp and poplar were used. The first four types are expensive and were mainly used in the 18th century in noblemen’s home distillation and partly in the 19th century in making top grades of vodka. In addition, their use was confined to certain geographic regions. Alder coal was used in private distillation until 1861. Lime coal was used even in the Soviet period until 1940. But virtually the main kind of coal in Russian distillation was birch coal which was the cheapest and the most widespread grade of coal. It was used throughout the 19th century on a mass scale in Tsarist Russia as an indispensable component of household life (for samovars) having a relatively high sorptive capacity.

Thus, it can be concluded that birch coal became widely used in production of vodka due to accessibility and low cost, and not due to its ability to form a certain taste of vodka. For that reason coco, fruit-stone coals are now coming into use because they have a higher activity and sorptive capacity.

The history of carbon filtration technology

In state wine storehouses the water-alcohol mixture was passed through a layer of granulated raw carbon that was loaded into copper columns tinned on the inside 700 mm in diameter and 4000 mm high. The number of columns in a battery ranged from 5 to 8. The processing rate of bread wine was extremely low, the time of seasoning in the column was at least 24 hours. Consumption rate of carbon ranged from 135 to 4100 g per bucket (approximately 1 dal).

Raw carbon contains in its pores a significant amount of gums and other heavy products of pyrolysis. Development of the carbon production technology, namely invention of the method of activating carbons with water steam, whereby impurities are burnt in the course of activation and the internal surface area of carbon is increased many-fold, made it possible to produce carbons having higher sorptive characteristics. Also, catalytic properties of carbons that determine the rate of redox reactions were significantly improved. In 1936 the All-Union Conference of Alcohol Industry adopted a resolution that methods of treating water-alcohol mixtures with activated carbon involving contact times of more than 30 minutes should not used and specified allowable carbon consumption rates: 16 g per dal for purification of 40% vodka, 20 g for 50% vodka and 23 g for 56% vodka. That is to say, the consumption rate of carbon was reduced by a factor of 8.5 to 256.

This was a significant technical step forward: instead of 5-8 columns connected in-series only one column could be operated at a considerably higher rate, the contact time of water-alcohol mixture and water was reduced from 24 to 0.5 hours.

A carbon column is a vertical vessel 4 meters high and 0.7 meters in diameter into which carbon is loaded. Filtration is carried out by the dynamic method, i.e. the water-alcohol mixture is passed under pressure through a stationary layer of carbon. Pressure is created by the head tank. The dynamic method is considered the best one for production of vodka, because it allows to control the processing parameters of the water-alcohol mixture: by changing the flow rate of the water-alcohol mixture it is possible to adjust organoleptic properties of resultant vodka, use various carbons, including mixtures of carbons. The dynamic method also makes it possible for the carbon to “manifest itself”, i.e. after a certain period of continuous operation the carbon goes over to the optimum mode and produces vodka with the best organoleptic characteristics. A carbon column is a vertical vessel 4 meters high and 0.7 meters in diameter into which carbon is loaded. Filtration is carried out by the dynamic method, i.e. the water-alcohol mixture is passed under pressure through a stationary layer of carbon. Pressure is created by the head tank. The dynamic method is considered the best one for production of vodka, because it allows to control the processing parameters of the water-alcohol mixture: by changing the flow rate of the water-alcohol mixture it is possible to adjust organoleptic properties of resultant vodka, use various carbons, including mixtures of carbons. The dynamic method also makes it possible for the carbon to “manifest itself”, i.e. after a certain period of continuous operation the carbon goes over to the optimum mode and produces vodka with the best organoleptic characteristics.

However, the use of the column also has disadvantages:

- a significant increase in weight share of aldehydes during start-ups and temporary stoppages of carbon columns

- a low processing rate of the water-alcohol mixture

- a high consumption rate of carbon (250 to 300 kg/50,000 to 150,000 dal of the water-alcohol mixture)

- non-uniform treatment of the water-alcohol mixture (channelling, self-sorting of carbon)

- high processing losses of carbon

- bulky equipment

- inconvenient maintenance

- impossibility of batch operation

Carbon columns require stable round-the-clock operation. Otherwise, during stoppages aldehydes are actively accumulated, producing irreparable waste. To wash a carbon column after a stoppage, up to 2 to 3 tons of the water-alcohol mixture are needed, which is now an inadmissible extravagance. Unstable operation also affects product quality, which becomes equally unstable. Today vodka is no longer in short supply, shops offer a broad variety of brands intended for various consumers. Under the existing market conditions many distilleries had to reduce their output, and this technology became inconvenient and rather expensive. Columns can be efficiently used only by vodka distilleries having large sales. Enterprises having small sales cannot achieve optimum prime cost and, what is more important, required product quality, and are forced out from the market by competitors offering higher quality. This is especially important for new enterprises, for whom quality is a precondition for survival.

To those who intend to start producing vodka and do not have appropriate experience, it should explained what is irreparable waste and how it is formed.

In all former Soviet republics there are vodka quality standards (such standards do not exist in other countries) specifying the amounts of methanol, fusil oils, ethers, and aldehydes. The amounts of methanol and fusil oils remain virtually unchanged in the course of vodka production, i.e. their amounts are determined immediately by the quality of incoming alcohol. Ethers and aldehydes, on the contrary, are formed as a result of ethyl alcohol oxidation in the course of carbon processing, since carbon plays two roles: that of the sorbent and that of the catalyst of redox reactions removing the harsh taste and odour of alcohol and creating the typical taste and flavour of vodka. That is to say, carbon forms the taste of vodka.

In the course of carbon processing, various components and chemical compounds are formed in vodka that determine its taste properties. Everything begins with the following reactions:

CH3 CH2. OH + O2 ---------> CH3 COH + H2O ---------> CH3COOH

Ethanol Etaldehyde (aldehyde) Acetic acid

The oxidation reaction at the first stage (ethanol to acetaldehyde) proceeds at a significantly higher rate compared to that of oxidation of acetaldehyde to acetic acid, which is why in the case of a reduction in reaction rate or stoppage of filtration an excess of acetaldehyde is formed, which is, unlike acetic acid, not sorbed by carbon and gets into the product. Acetaldehyde has a harsh odour and taste and aggravate the alcohol withdrawal syndrome, which is why the content of aldehyde is regulated. Standards for aldehyde content are different in various countries, e.g. 4 mg/dm3 in Ukraine, 3 mg/dm3 in Russia and 2 mg/dm3 in Kazakhstan for vodkas based on Lux alcohol. Vodka having aldehyde content above the admissible level is considered irreparable waste, because aldehyde content can be reduced either at the alcohol distillery, or by using special sorbents that are rather expensive and do not ensure required taste properties.

In 1980-90s, several enterprises adopted the so-called Poltovchanka system, a method of processing the water-alcohol mixture in a suspended carbon layer, which is an alternative to the dynamic method. The system allowed the enterprises to operate in both batch and continuous modes. Preparation of water-alcohol solutions is carried out simultaneously with introduction of the sorbent which is subsequently removed using filters. The sorbent and ingredients are mixed with compressed air. Thanks to the turbulent mode of movement and small sizes of carbon grains (they should range from 0.2 to 0.4 mm), intensive mass exchange takes place between the water-alcohol mixture and active carbon. Further improvements in this technology made it possible to use, apart from carbon adsorbent, such absorbents as modified starch, rye and wheat flour, eggwhite, etc. In addition, the system offered the possibility of preparing the water-alcohol mixture in the continuous flow. In 1980-90s, several enterprises adopted the so-called Poltovchanka system, a method of processing the water-alcohol mixture in a suspended carbon layer, which is an alternative to the dynamic method. The system allowed the enterprises to operate in both batch and continuous modes. Preparation of water-alcohol solutions is carried out simultaneously with introduction of the sorbent which is subsequently removed using filters. The sorbent and ingredients are mixed with compressed air. Thanks to the turbulent mode of movement and small sizes of carbon grains (they should range from 0.2 to 0.4 mm), intensive mass exchange takes place between the water-alcohol mixture and active carbon. Further improvements in this technology made it possible to use, apart from carbon adsorbent, such absorbents as modified starch, rye and wheat flour, eggwhite, etc. In addition, the system offered the possibility of preparing the water-alcohol mixture in the continuous flow.

An undeniable advantage of this method is the possibility to operate in the batch mode. However, significant additional expenses are required for purification of vodka from a high content of finely dispersed dust. To make a crystal-clear vodka from that having carbon colour and zero transparency, a multi-stage filtration system is needed, including coarse filters, a filter press and cartridge-type filters. Expenses on final filtration before filling are also increased. The method increases labour costs for treatment of the water-alcohol mixture and cleaning of production facilities. If we consider taste properties of vodka produced by this method, the very fact that this technology is not used by any factory producing well-known brands speaks for itself.

Other technologies of treating the water-alcohol mixture also exist, but they did not become widespread.

These technologies have significant disadvantages in conditions of modern manufacturing. Today, more advanced approaches are needed, that result in low prime cost and high quality of the products.

Modern realities

So, let us return to nowadays. We now live in the 21st century. So what is carbon processing today? This is a fundamental question, because our efficiency and competitiveness depend on how modern and objective we are.

Common consumers are now told tall tales about unique methods of purification of a certain vodka. However, a real specialist would smile ironically in this case, because purification of vodka determined quality of the product throughout the last century until the advent of “Highly purified”, “Extra” and “Lux” alcohols. These alcohols are significantly different from those used before that are now called raw alcohols. Table 1 shows physico-chemical qualitative characteristics of alcohols that are in reality even lower. Modern alcohols exhibit an extremely low content of fusil oils, methanol and other impurities that have objectionable smell and toxic properties. What was previously removed by carbon, is removed much more effectively at alcohol distilleries by modern rectification systems.

Table 1. Physico-chemical qualitative characteristics of rectified ethyl alcohol

|

Parameter

|

Standard values for a specific alcohol

|

|

|

“Lux”

|

“Extra”

|

Highly purified

|

|

Volume share of ethyl alcohol, %, no less than

|

96.3

|

96.5

|

96.2

|

|

Purity test using sulfuric acid

|

Pass

|

|

Oxidizability test, at 200°C, min, no less than

|

22

|

20

|

15

|

|

Weight concentration of aldehydes, in terms of acetic aldehyde, in absolute alcohol, mg/dm3, no more than

|

2

|

2

|

4

|

|

Weight concentration of fusil oil in terms of the mixture of isoamyl and isobutyl alcohols (3:1), in absolute alcohol, mg/dm3, no more than

|

2

|

3

|

4

|

|

Weight concentration of ethers, in terms of acetic ether, in absolute alcohol, mg/dm3, no more than

|

18

|

25

|

30

|

|

Volume share of methyl alcohol versus absolute alcohol, %, no more than

|

0,03

|

0,03

|

0,05

|

|

Weight concentration of free acids (without CO2) in absolute alcohol, mg/dm3, no more than

|

8

|

12

|

15

|

|

Content of furfurol

|

Not allowed

|

The approach to water treatment has changed as well. Modern water conditioning systems make it possible to purify water to any level of purity, including distilled. Today, any distillery has a water conditioning system.

So, what is the water-alcohol mixture purified from? In actual fact, carbon processing is now used not for purification, but for shaping the taste of vodka by means of the chemical processes we were talking about earlier. As a rule, removal of impurities from alcohol is not a direct consequence of their adsorption, but a result of carbon-catalyzed redox reactions.

The role of purification was artificially revoked lately by some companies to stand out among a hundred of brands. Once again, people resumed to use starch and milk as well as multi-stage carbon purification systems, although they had to use a more rigid water and less pure alcohols in these processing options, because modern water-alcohol mixtures are so pure that the coagulant (milk, starch) just cannot precipitate.

New technologies have emerged: Silver Filtration, Platinum Filtration, Gold Filtration, Diamond Filtration, Pearl Filtration whose developer is Technofilter Research-and-Manufacturing Enterprise Ltd. We intentionally put them in a single line, like many people do who have heard about them, but for the ultimate purpose of distinguishing one from the other. It should be emphasized that our technologies were developed thanks to vodka producers; some of them were intended for publicity campaigns (Gold filtration, Diamond filtration, Pearl filtration), others, such as Silver filtration and Platinum filtration, appeared as a result of long-term research, proved themselves at more than 200 enterprises of the industry and, what we would like to emphasize particularly, are an evolutionary successor to the dynamic method of treating the water-alcohol mixture and vodka, which is considered a classic and the most effective one. And, what is important: the DYNAMIC method has now become a BATCH method.

Please take a closer look at these technologies on specialized pages of our site.

|

|

|